Cam Basics

3 posters

KBIT FORUM :: Car Talk :: Car Tech

Page 1 of 1

Cam Basics

Cam Basics

Found this article when reading through some car articles on the internet and feel its very educational

If the cylinder heads represent the aerobic side of an engine, and the rotating assembly is its muscle, then the camshaft must be the brain. The cam is the component that signals when the valves open and close, timing the valve events to create power.

Appropriately, the cam is also the most complex and often baffling component in an internal combustion engine. That lumpy-bumpy stick with all the lobes commands a whole vocabulary of terms that can be especially confusing. This brief primer on camshaft basics will decipher many of those terms and explain how a camshaft works. Once you have a general understanding of what all this cam talk is about, you can use that knowledge to pick the cam that's best for your engine. We can narrow the discussion of how a cam works down to lift, duration, and overlap as the three most critical components of cam design. We'll save the discussion of overlap for a separate story.

Lift

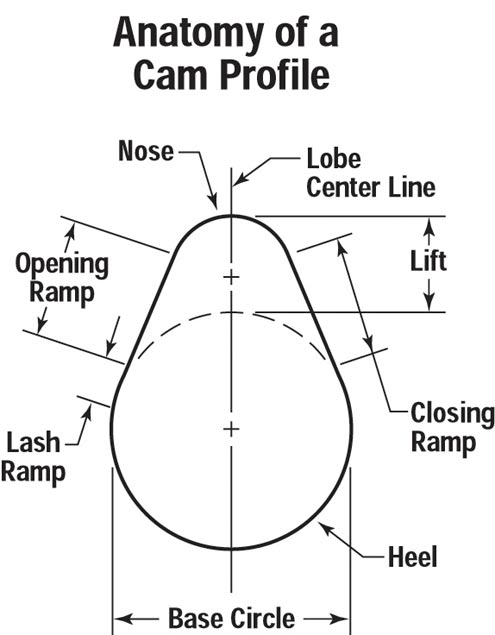

A camshaft transforms rotating motion into linear, or straight-line, motion. Whoever designed the first camshaft lobe probably had no idea how complex this egg-shaped device would become. All eccentrics are based on a circle. In camshaft terms, this is called the base circle. From there, you add an eccentric, or lobe, that creates lift. The height of the lobe above the circle's radius is the lobe lift of the camshaft.

Let's say we have a lobe lift measuring 0.333 inch. Since the Chevy engines that we're interested in are pushrod V-8s, we also must include a rocker arm. The rocker is actuated by the vertical motion of the lifter and pushrod and multiplies lobe lift by the rocker arm ratio. For the classic small-block, the standard ratio is 1.5:1. Multiplying the lobe lift times the rocker ratio will produce gross valve lift (0.333-inch lobe lift times 1.5:1 rocker ratio = 0.499-inch gross valve lift).

Higher rocker ratios can significantly increase valve lift, but this requires stiffer components that can become rather expensive. However, if you have a cylinder head that can flow more air at greater valve lifts, there is power to be made. Creating more lobe lift is not as easy as just making the eccentric taller. Because of physical limitations between the lifter and the cam, more lobe lift requires more distance to create the opening and closing ramps. This is created by extending the length of the ramps.

Duration

Duration is the term given to the amount of crank movement (in crankshaft degrees) that the lobe creates lift by pushing the lifter off the base circle. We'll go over each of these specs to make them easier to understand. If you look at the size of a camshaft gear relative to the crank gear, you'll notice that the cam gear is twice the size of the crank gear. This means that the camshaft spins at half crankshaft speed. To make it easier to understand cam duration, most cam specs are given in crankshaft degrees.

Duration is expressed as the number of degrees of crankshaft rotation used by the lobe to move the lifter. Since the exact point at which the lifter starts to move can be difficult to establish, cam companies use a checking height to establish this movement. The SAE standard is 0.006 inch of lifter rise off the base circle of the cam. Unfortunately, not all companies use this standard. Because different checking heights can make a large difference in the advertised duration of a camshaft, the industry established the common checking height of 0.050 inch for duration. This is the only way to accurately compare duration figures of camshafts >> from different manufacturers.

For each lobe there is an opening and closing point. Duration is expressed as the number of degrees that the crankshaft rotates between these two points. For example, the intake lobe on a Crane PowerMax H-288 cam has an advertised duration of 288 degrees and a 0.050-inch duration of 226 degrees. The 0.050-inch duration will always be less than the advertised duration because it measures between opening and closing points on the lobe that are closer together where the tappet reaches 0.050-inch rise. The advertised duration for Crane cams is measured at 0.004-inch tappet lift, which encompasses a greater rotation, so the number of degrees will always be higher.

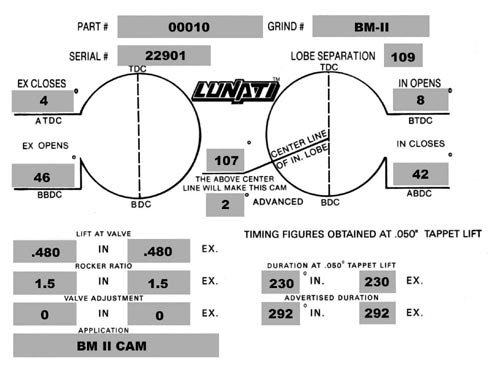

We should also discuss where these opening and closing points occur. Intake opening (IO) usually occurs before top dead center (BTDC), while intake closing (IC) happens after bottom dead center (ABDC). For the exhaust side, exhaust opening (EO) occurs before bottom dead center (BBDC) and exhaust closing (EC) after top dead center (ATDC). These data points are listed on the cam card that comes with each new camshaft. These points can also be verified with the cam in the engine when the camshaft is degreed. If you're not sure of the size of the cam but you know the intake and exhaust opening and closing points, you can determine the duration by simply adding the opening and closing points to 180 degrees. For example, the Crane PowerMax 288 cam's 0.050-inch tappet lift numbers are IO at 4 degrees BTDC and IC at 42 degrees ABDC. Add these to 180 degrees and you get 226 degrees (4 + 42 +180 = 226 degrees). This technique also applies to the exhaust lobe.

Intake Centerline

Now that you're conversant with lift and duration, let's add another detail called the lobe centerline. >> Imagine looking at a lobe split directly down the middle as viewed from the end of the cam. This line would create what's called the intake centerline. The exhaust lobe also has a similar centerline. If you look at a typical cam card, the intake centerline is also expressed in crankshaft degrees ATDC. For example, a Comp Cams 268 Xtreme Energy cam has an intake centerline of 106 degrees ATDC. You can use this information to degree the cam and find the intake centerline for cylinder No. 1 to ensure the cam is installed in the proper relationship to the crankshaft.

When degreeing the cam, it's possible that the cam may not always check out in the right place. For example, let's say you degree this cam in your engine and discover the intake centerline is actually installed at 112 degrees ATDC compared to the 106 degree specifications. This means the cam is retarded relative to the cam card spec. To position the cam at 106, the cam must be advanced 6 degrees. Conversely, if we found the cam at 103 degrees ATDC, this is advanced compared to the 106 centerline. Repositioning the intake centerline at 106 degrees ATDC would require retarding the cam 3 degrees.

Single- and Dual-Pattern Cams

We're slowly assembling the building blocks that make up a camshaft. If you've ever looked at the card that comes with a new cam, then perhaps you've noticed that sometimes the intake and exhaust duration specs are similar and other times they are not. A single-pattern cam uses the same duration and lift numbers for both the intake and exhaust lobes, while a dual-pattern cam often employs a longer duration and more lift on the exhaust side. A dual-pattern cam employs more exhaust duration in order to compensate for a weak exhaust port, which is often the case with stock heads.

An interesting phenomenon is now occurring with regard to single- and dual-pattern cams. Before the days of excellent aftermarket heads for the small-block Chevy, most cam manufacturers built single-pattern cams. Once these companies discovered that dual-pattern cams made more power, these cams became the new hot ticket. The emerging pattern now is that most aftermarket heads offer such strong exhaust ports that the shift to a single-pattern cam will make more power. Expect to see the cam companies again move back to an emphasis on single-pattern cams as cylinder heads continue to improve.

Cam Selection

It's tough to condense this massive subject down into a few short paragraphs, but the key to cam selection is to be brutally truthful when it comes to how you intend to use the engine in question. If you intend to build a daily driver, keep the duration short with an eye toward decent lift for the length of the duration. Don't succumb to the temptation to put the biggest cam you can find into your daily driver. All the cam companies offer comprehensive cam selection procedures based on compression, cruise rpm at 60 mph, and transmission type. This is an attempt to establish a torques cam selection that will not kill low-speed power with too much overlap.

Conclusion

We really needed about 10 more pages to adequately cover the topic of camshaft basics, but short of that, lift and duration are the most critical points to understanding cam timing. Proper camshaft timing is critical to extracting the most power from any engine and it's difficult to hit the power bull's-eye on the first try. If camshafts seem a bit confusing, you're on the right track to zeroing in on understanding the basics. Once you've mastered the basics, you can then move on to more complex issues like overlap, asymmetrical lobes, inverted flank roller profiles, and intriguing stuff like that. Hey, it's gotta be more fun than collecting butterflies.

If the cylinder heads represent the aerobic side of an engine, and the rotating assembly is its muscle, then the camshaft must be the brain. The cam is the component that signals when the valves open and close, timing the valve events to create power.

Appropriately, the cam is also the most complex and often baffling component in an internal combustion engine. That lumpy-bumpy stick with all the lobes commands a whole vocabulary of terms that can be especially confusing. This brief primer on camshaft basics will decipher many of those terms and explain how a camshaft works. Once you have a general understanding of what all this cam talk is about, you can use that knowledge to pick the cam that's best for your engine. We can narrow the discussion of how a cam works down to lift, duration, and overlap as the three most critical components of cam design. We'll save the discussion of overlap for a separate story.

Lift

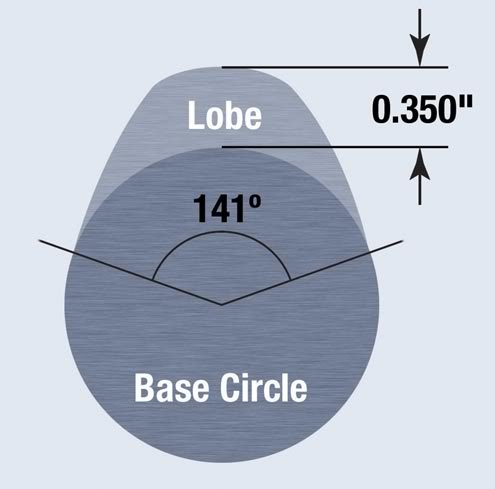

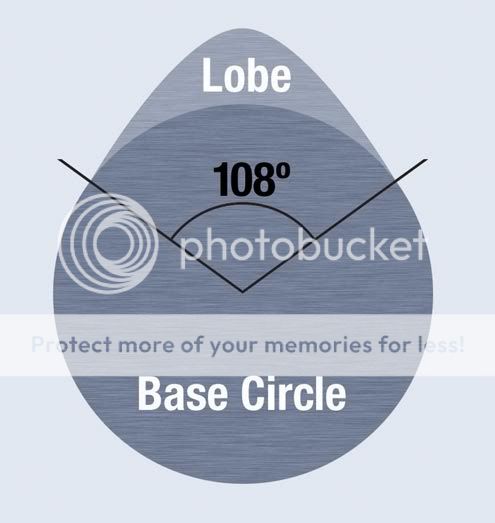

A camshaft transforms rotating motion into linear, or straight-line, motion. Whoever designed the first camshaft lobe probably had no idea how complex this egg-shaped device would become. All eccentrics are based on a circle. In camshaft terms, this is called the base circle. From there, you add an eccentric, or lobe, that creates lift. The height of the lobe above the circle's radius is the lobe lift of the camshaft.

Let's say we have a lobe lift measuring 0.333 inch. Since the Chevy engines that we're interested in are pushrod V-8s, we also must include a rocker arm. The rocker is actuated by the vertical motion of the lifter and pushrod and multiplies lobe lift by the rocker arm ratio. For the classic small-block, the standard ratio is 1.5:1. Multiplying the lobe lift times the rocker ratio will produce gross valve lift (0.333-inch lobe lift times 1.5:1 rocker ratio = 0.499-inch gross valve lift).

Higher rocker ratios can significantly increase valve lift, but this requires stiffer components that can become rather expensive. However, if you have a cylinder head that can flow more air at greater valve lifts, there is power to be made. Creating more lobe lift is not as easy as just making the eccentric taller. Because of physical limitations between the lifter and the cam, more lobe lift requires more distance to create the opening and closing ramps. This is created by extending the length of the ramps.

Duration

Duration is the term given to the amount of crank movement (in crankshaft degrees) that the lobe creates lift by pushing the lifter off the base circle. We'll go over each of these specs to make them easier to understand. If you look at the size of a camshaft gear relative to the crank gear, you'll notice that the cam gear is twice the size of the crank gear. This means that the camshaft spins at half crankshaft speed. To make it easier to understand cam duration, most cam specs are given in crankshaft degrees.

Duration is expressed as the number of degrees of crankshaft rotation used by the lobe to move the lifter. Since the exact point at which the lifter starts to move can be difficult to establish, cam companies use a checking height to establish this movement. The SAE standard is 0.006 inch of lifter rise off the base circle of the cam. Unfortunately, not all companies use this standard. Because different checking heights can make a large difference in the advertised duration of a camshaft, the industry established the common checking height of 0.050 inch for duration. This is the only way to accurately compare duration figures of camshafts >> from different manufacturers.

For each lobe there is an opening and closing point. Duration is expressed as the number of degrees that the crankshaft rotates between these two points. For example, the intake lobe on a Crane PowerMax H-288 cam has an advertised duration of 288 degrees and a 0.050-inch duration of 226 degrees. The 0.050-inch duration will always be less than the advertised duration because it measures between opening and closing points on the lobe that are closer together where the tappet reaches 0.050-inch rise. The advertised duration for Crane cams is measured at 0.004-inch tappet lift, which encompasses a greater rotation, so the number of degrees will always be higher.

We should also discuss where these opening and closing points occur. Intake opening (IO) usually occurs before top dead center (BTDC), while intake closing (IC) happens after bottom dead center (ABDC). For the exhaust side, exhaust opening (EO) occurs before bottom dead center (BBDC) and exhaust closing (EC) after top dead center (ATDC). These data points are listed on the cam card that comes with each new camshaft. These points can also be verified with the cam in the engine when the camshaft is degreed. If you're not sure of the size of the cam but you know the intake and exhaust opening and closing points, you can determine the duration by simply adding the opening and closing points to 180 degrees. For example, the Crane PowerMax 288 cam's 0.050-inch tappet lift numbers are IO at 4 degrees BTDC and IC at 42 degrees ABDC. Add these to 180 degrees and you get 226 degrees (4 + 42 +180 = 226 degrees). This technique also applies to the exhaust lobe.

Intake Centerline

Now that you're conversant with lift and duration, let's add another detail called the lobe centerline. >> Imagine looking at a lobe split directly down the middle as viewed from the end of the cam. This line would create what's called the intake centerline. The exhaust lobe also has a similar centerline. If you look at a typical cam card, the intake centerline is also expressed in crankshaft degrees ATDC. For example, a Comp Cams 268 Xtreme Energy cam has an intake centerline of 106 degrees ATDC. You can use this information to degree the cam and find the intake centerline for cylinder No. 1 to ensure the cam is installed in the proper relationship to the crankshaft.

When degreeing the cam, it's possible that the cam may not always check out in the right place. For example, let's say you degree this cam in your engine and discover the intake centerline is actually installed at 112 degrees ATDC compared to the 106 degree specifications. This means the cam is retarded relative to the cam card spec. To position the cam at 106, the cam must be advanced 6 degrees. Conversely, if we found the cam at 103 degrees ATDC, this is advanced compared to the 106 centerline. Repositioning the intake centerline at 106 degrees ATDC would require retarding the cam 3 degrees.

Single- and Dual-Pattern Cams

We're slowly assembling the building blocks that make up a camshaft. If you've ever looked at the card that comes with a new cam, then perhaps you've noticed that sometimes the intake and exhaust duration specs are similar and other times they are not. A single-pattern cam uses the same duration and lift numbers for both the intake and exhaust lobes, while a dual-pattern cam often employs a longer duration and more lift on the exhaust side. A dual-pattern cam employs more exhaust duration in order to compensate for a weak exhaust port, which is often the case with stock heads.

An interesting phenomenon is now occurring with regard to single- and dual-pattern cams. Before the days of excellent aftermarket heads for the small-block Chevy, most cam manufacturers built single-pattern cams. Once these companies discovered that dual-pattern cams made more power, these cams became the new hot ticket. The emerging pattern now is that most aftermarket heads offer such strong exhaust ports that the shift to a single-pattern cam will make more power. Expect to see the cam companies again move back to an emphasis on single-pattern cams as cylinder heads continue to improve.

Cam Selection

It's tough to condense this massive subject down into a few short paragraphs, but the key to cam selection is to be brutally truthful when it comes to how you intend to use the engine in question. If you intend to build a daily driver, keep the duration short with an eye toward decent lift for the length of the duration. Don't succumb to the temptation to put the biggest cam you can find into your daily driver. All the cam companies offer comprehensive cam selection procedures based on compression, cruise rpm at 60 mph, and transmission type. This is an attempt to establish a torques cam selection that will not kill low-speed power with too much overlap.

Conclusion

We really needed about 10 more pages to adequately cover the topic of camshaft basics, but short of that, lift and duration are the most critical points to understanding cam timing. Proper camshaft timing is critical to extracting the most power from any engine and it's difficult to hit the power bull's-eye on the first try. If camshafts seem a bit confusing, you're on the right track to zeroing in on understanding the basics. Once you've mastered the basics, you can then move on to more complex issues like overlap, asymmetrical lobes, inverted flank roller profiles, and intriguing stuff like that. Hey, it's gotta be more fun than collecting butterflies.

VictorGR- Admin

- Posts : 87

Join date : 2009-09-16

Age : 38

Location : Point Cook, Melbourne Vic

Re: Cam Basics

Re: Cam Basics

Camshafts come in either flat-tappet (bottom) or roller (top) versions. Within each of these styles, you can opt for either a solid or hydraulic version of the cam and lifters. Roller cams offer more lift for the same amount of duration compared to flat-tappet cams

Of the two styles, hydraulic cams are far more popular than solid cams, mainly because solid cams require periodic maintenance to set the valve lash. However, with quality parts like a good poly lock, setting lash is an infrequent requirement

The height of the lobe above the base circle is the amount of lift generated by a cam lobe. Multiply lobe lift times the rocker-arm ratio to establish valve lift. For example, a 0.350-inch lobe times a rocker ratio of 1.5 equals a gross valve lift of 0.525 inch

A lobe with 108 degrees of duration at 0.050-inch tappet lift multiplied by 2 (because the cam spins at half the crankshaft speed) equals a duration of 216 degrees, which is a relatively mild lobe

Degreeing a camshaft is not required for installation, but it’s good to know exactly where the cam is. Our experience is that cams usually bolt in within 1 to 2 degrees of their intended position, but we’ve also seen them installed and retarded by as much as 4 degrees

The camshaft spins at exactly half the crankshaft speed because the cam gear is twice the diameter of the crank gear. This timing-gear set offers several keyway slots in the crank gear that allows the engine builder to advance or retard the cam

This is a drawing of a cam profile that shows various areas of a typical cam lobe

Each manufacturer creates its own cam timing card. This is a Lunati cam card for a single-pattern 230 at 0.050 hydraulic cam. The top half of the card indicates the opening and closing points of the exhaust and intake lobes at the 0.050-inch checking height. Notice that the cam is ground 2 degrees advanced since the intake centerline (A) is at 107 degrees while the lobe separation angle (B) is 109 degrees. The lower half of the card identifies valve lift for the intake and exhaust as well as both advertised and 0.050-inch duration figures. A cam timing card will tell you just about everything you need to know about a cam

VictorGR- Admin

- Posts : 87

Join date : 2009-09-16

Age : 38

Location : Point Cook, Melbourne Vic

Re: Cam Basics

Re: Cam Basics

good post man, haven't finish it but will do it in a slow......very slow.....manner hahha

Re: Cam Basics

Re: Cam Basics

Top_2JZE34 wrote:THX!

welcome if u know any good articles u can post them up as well all are welcomed, lets help this forum grow

VictorGR- Admin

- Posts : 87

Join date : 2009-09-16

Age : 38

Location : Point Cook, Melbourne Vic

KBIT FORUM :: Car Talk :: Car Tech

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|